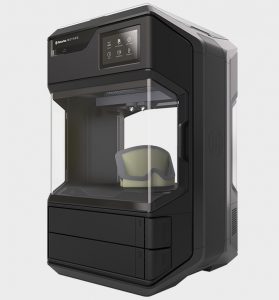

RS Components introduces Makerbot Method 3D Printer

Author: EIS Release Date: Jul 25, 2019

RS Components today announced it is shipping the Makerbot Method 3D, which has been designed to bridge the gap between industrial and desktop 3D printing.

The unit targets engineers and designers who use 3D modelling software and need to create product prototypes rapidly for a range of purposes, such as to accelerate product development or to ensure the viability of parts before moving to volume production.

A key feature of the Method is its printing speed, which RS Components claims is up to two times faster than other popular desktop 3D printers, based on a range of tests using the same layer height and in-fill density settings.

The Method has a circulating heated chamber, which controls the heat of each layer and delivers a dimensional accuracy of ±0.2mm. The unit also has a metal frame that runs the full length of the body, which leads to more consistent prints with better part accuracy and fewer failures, RS Components says.

The Method also comes with dual extruders, which offer lengthened thermal cores and optimised torque. In addition, it has a suite of sensors with a network of 21 intelligent devices embedded throughout to deliver enhanced control over the printing process.

Other specifications include: layer resolution from 400 down to 20 microns; maximum build volumes of 19x19x19.6cm for single- and 15.2x19x19.6cm for dual-extrusion processes; and connectivity options including WiFi, Ethernet or USB drive.

Also supplied with the printer is material from Makerbot, including a spool of “tough” and a spool of “precision dissolving PVA”, which enables the removal of support material without compromising part design or dimensional accuracy.

The printer comes with a 12-month warranty and is compatible with a range of CAD software packages including SolidWorks, Autodesk, CATIA, Rhino and TinkerCAD.

The MakerBot Method is now shipping from RS in the EMEA and Asia Pacific regions.