Automotive Ultra-Compact 1 mm² MOSFETs

Author: EIS Release Date: Jan 7, 2021

ROHM’s ultra-compact MOSFETs are suitable for high-density applications such as ADAS and automotive ECUs

ROHM’s RV8C010UN, RV8L002SN, and BSS84X ultra-compact AEC-Q101 qualified MOSFETs offer a 1 mm² size that delivers automotive-grade reliability. These MOSFETs are suitable for high-density applications such as ADAS and automotive ECUs, improving heat dissipation and mounting reliability.

ROHM’s RV8C010UN, RV8L002SN, and BSS84X ultra-compact AEC-Q101 qualified MOSFETs offer a 1 mm² size that delivers automotive-grade reliability. These MOSFETs are suitable for high-density applications such as ADAS and automotive ECUs, improving heat dissipation and mounting reliability.

For automotive parts, automated optical inspection (AOI) is performed after mounting to ensure reliability. However, with bottom electrode components, the solder joint cannot be verified since the terminals are not visible, making it difficult to conduct a visual inspection that meets automotive standards. ROHM has solved these issues with its original wettable flank technology that ensures an unprecedented side electrode height of 125 µm in the 1.0 mm × 1.0 mm size and leading to increased adoption by several vehicle manufacturers.

The continuing electrification of vehicles in recent years has significantly increased the number of electronic and semiconductor components used per vehicle. Consequently, the need for a dramatic increase in component density has become even more important. For example, the average number of multilayer ceramic capacitors (MLCC) and semiconductor components installed in a single automotive ECU is expected to increase by 30%. At the same time, for high-density automotive applications that demand greater miniaturization, studies are currently underway on bottom electrode packages that can achieve excellent heat dissipation in a compact form factor.

Extremely high solder mounting reliability is achieved during AOI in automotive systems that require high quality. The bottom electrode package simultaneously provides both breakthrough miniaturization and high heat dissipation (normally in a trade-off relationship), making it ideal for ADAS and automotive ECUs featuring higher board densities.

- Original wettable flank technology ensures a side electrode height of 125 µm

- In conventional bottom electrode packaging, the sides of the lead frame cannot be plated, making it difficult to conduct AOI to verify the solder height required for automotive applications

- MOSFETs leverage proprietary wettable flank technology to ensure a breakthrough side electrode height of 125 µm in the 1.0 mm × 1.0 mm size

- Enables stable toe fillet formation even with bottom electrode packages, allowing the solder condition to be verified by AOI after mounting

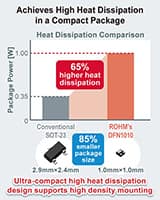

- Ultra-compact high heat dissipation MOSFETs support high-density mounting

- Same performance as the 2.9 mm × 2.4 mm package (SOT-23) but in the smaller 1.0 mm × 1.0 mm package (DFN1010) reducing mounting area by approx. 85%

- High heat dissipation bottom electrode structure improves heat dissipation (which normally decreases with size) by up to 65% over SOT-23

- RV8C010UN, RV8L002SN, and BSS84X are ideal for automotive ECUs and ADAS that are seeing higher board densities following increasing performance

- Switching and reverse connection protection applications

- Autonomous driving control ECUs

- Car infotainment

- Engine control ECUs

- Drive recorders

- ADAS applications